- Key Features

- Continuous reading leak detector

- Instant response to leak correction

- Data-logging and bar code reader support

- Ideal for large temperature-sensitive items

The FCO794 features pressure and temperature compensation giving automatic correction to the leak reading regardless of the actual test pressure and temperature. The leak reading displayed is the equivalent leak that would occur at the pressure and temperature entered in the test data. This negates the need to constantly monitor the set test pressure.

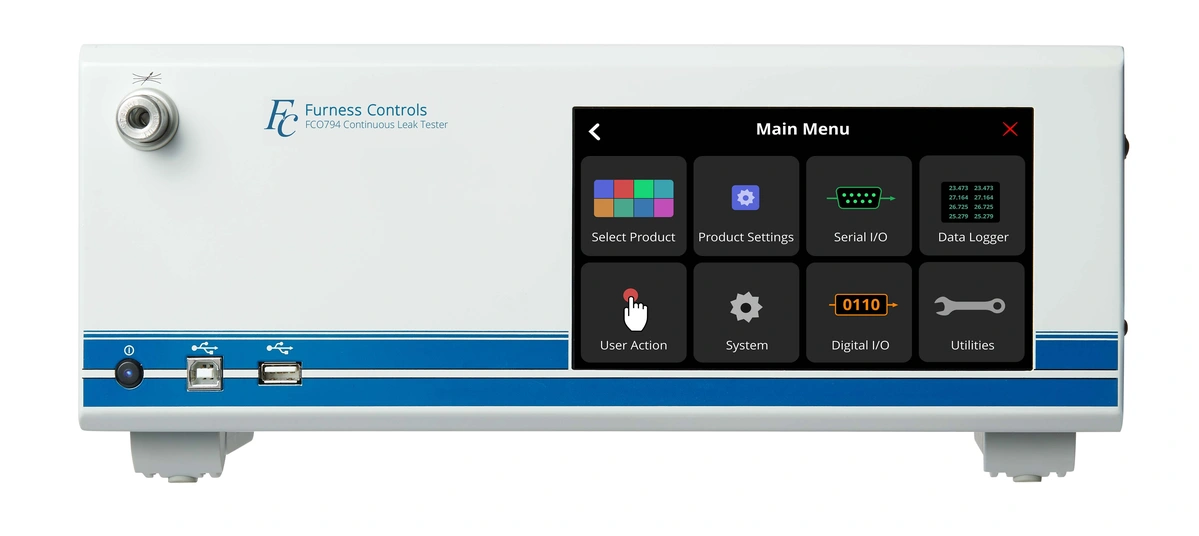

Like all of the flagship leak testing models from Furness Controls, this device is highly flexbile in terms of configuration and connectivity, and is also easy to use through the intuitiuve colour touchscreen. Control through a PLC can be achieved using most industrial protocols (Profinet, profibus, modbus etc.), and control from a PC is possible over usb and ethernet. Flexibile Digital I/O and configurable pneumatic outputs enable the FCL794 to run an entire test setup independently, with external jigs, sensors and alarms controlled directly from the instrument.

The FCO794 can store 300 product programs, each consisting of 16 individual test steps, meaning that your entire test regime can be configured and executed at will. The vibrant LCD screen (or attached external lamps) clearly indicates passes & fails, as well as statistical information such as pass rate per batch. The same information is available remotely, easlily integrating the leak tester with your auditing regime.

For many years the FCO794 has been used to test gas appliance sub-assemblies to all relevant European Standards. Designed specifically to meet the requirements of the gas appliance industry, the FCO794 combines accuracy, reliability and ease of use. Ideally suited for use in the gas industry, the FCO794 is also highly suitable for testing many other product types such as filters, heat exchangers and large vessels. So, if you are looking for a versatile leak tester that allows product fault rectification while live-testing, you've found the market leader, the FCO794.

-

Performance

Rapid test times with globally renowned accuracy levels over a wide range of pressures (from vacuum to 30bar)

-

Integration

PLC controlled, user operated, or can control the whole jig itself

-

Touchscreen

Easy to use high-resolution graphical display with capacitive touch

-

Flexible

300 fully-adjustable programs

-

Datalogger

Store and retrieve up to 1,000,000 results

-

Communications

Industrial protocols, ethernet, serial and RS485

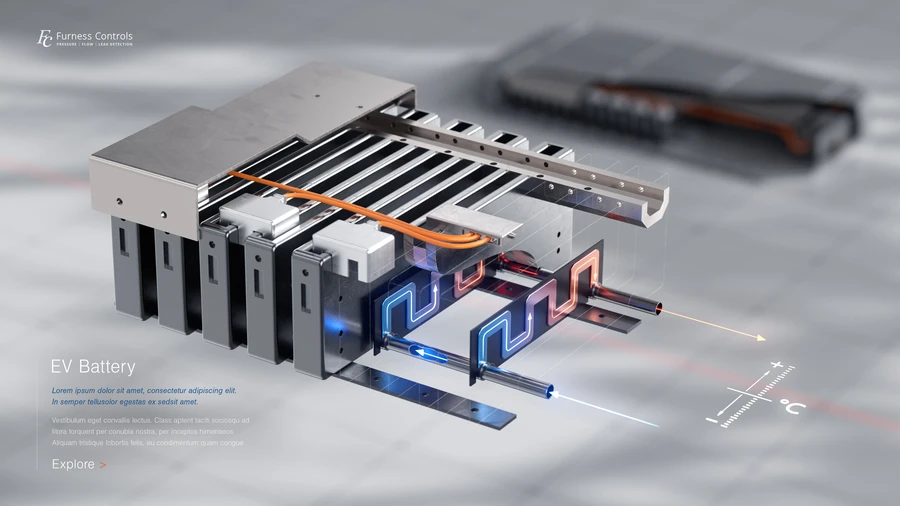

The FCO794 provides an ideal solution for EV battery enclosure testing, as well as flow and leak testing on domestic gas appliances.

EV Battery Enclosure Testing

Enclosures for EV batteries are often complicated multi-port assemblies with many potential points of failure, and usually contain large open volumes to complicate leak testing. Using the FCO794 the enclosure can be continuously tested while adjustments to seals are made. Furthermore, with a large isolated volume used as the pressure source, small leaks in the enclosure are easily detected because drops in pressure translates to larger movements in air between the volume and the enclosures, amplifying sensitivity.