- Key Details

- Air and gas flows from 0.01 ml/min to 10,000 l/min

- Automatic pressure & temperature compensation

- 300 configurable products and 300 tests as standard

- Automatic pressure regulation variant available

- Partial blockage identification and cross sectional area testing

Flow Testers with World-Leading Accuracy

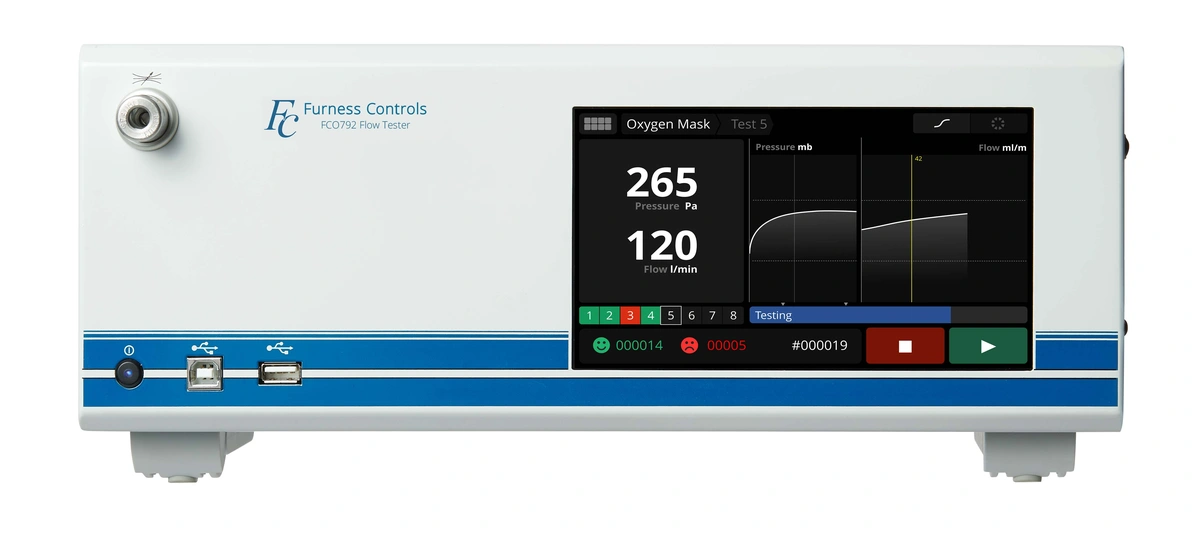

The FCO782 and FCO792 are the newest iterations of the highly successful, production line leak testers from Furness Controls. Building on the success of the FCO752, these high specification automatic flow testers are built with the world-class accuracy and reliability expected from global leaders in the industry

-

Performance

Rapid test times with globally renowned accuracy levels over a wide range of pressures (from vacuum to 30bar)

-

Communications

PROFINET and EtherNet/IP allows easy connection to a PLC; additional communication options include RS232, RS485 and USB

-

Integration

Pnuematic outputs and Digital I/O ensure that these leak testers can integrate with many jig setups

-

Flexible options

These flow testers can check for partial blockages within products and components or check cross-sectional areas (against known standards). By switching the instruments to operate in "pressure" mode, changes in generated back pressure as low as 0.1 Pa can be determined

-

Touchscreen

The control interface for the device is a generously-sized colour capacitive touch screen display. It features intuitive menu navigation for programming and provides many display modes, including operational status and instantaneous graphical results during testing

-

Data logger

The built-in datalogger stores test results locally for easy recall or export. Results can be analysed on-device using the high clarity display, or exported via USB memory stick for analysis on PC

Intuitive & fast touchscreen display

- Clear numerical values, detailed graphing and easy-touch button

- Quickly choose between 300 configurable products, each with up to 16 customisable steps

- Data Logger function allows you to browse and export all of the data from your last 1,000,000 product tests

- Change settings and configure tests quickly and easily with the intuitive icon-based menu system

These flow testers offer a perfect platform to reduce testing station costs and complexity by negating the requirement for a PLC altogether. Through the use of electrical I/O and pneumatic outputs, the instruments themselves can control the entire test station.

Communications

- User-programmable electrical I/O connectors

- User-programmable pneumatic Outputs

- Modern industrial communication interfaces such as PROFINET and EtherNet/IP

- Other communication modes such as RS232, RS485, USB and standard TCP/IP over Ethernet