- Key Details

- Leak sensitivity down to 0.1 Pa or 0.01 ml/min

- Perform multiple test types in simple or complex sequences

- Suitable for both standalone use and integration into large systems

- Multiple pressure (vacuum to 30bar) and leak range options

- Differential pressure decay, ramp, blockage, and sealed-item test types

Advanced Differential Leak Testing

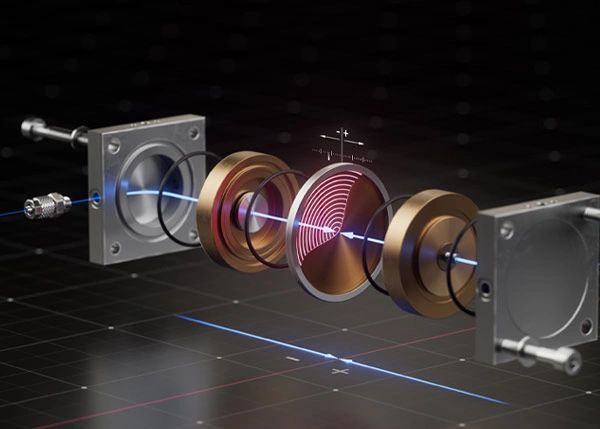

The FCO780 and FCO790 are the newest iterations of the highly successful, production line leak detector from Furness Controls. Building on the success of the FCO750 and the original FCO290, these high specification automatic leak testers are built with the world-class accuracy and reliability expected from global leaders in the industry

-

Performance

Rapid test times with globally renowned accuracy levels over a wide range of pressures (from vacuum to 30bar)

-

Communications

PC and PLC connections including RS232, RS485,USB, Ethernet, PROFINET and EtherNet/IP

-

Integration

Integrate in jigs and other machinery with programmable electrical I/O and pneumatic output options. A barcode scanner can select specific product test parameters

-

Flexible options

Configure up to 300 products using combinations of up to 16 different tests, including pressure decay, blockage, ramp, dump and bell tests

-

Touchscreen

Large colour touchscreen for intuitive device control and display of high resolution graphs

-

Data logger

Built-in data logger aids traceability by storing not only test results but also the pressure profile for each test, allowing for in-depthanalysis of all test results.

Flexible test types

-

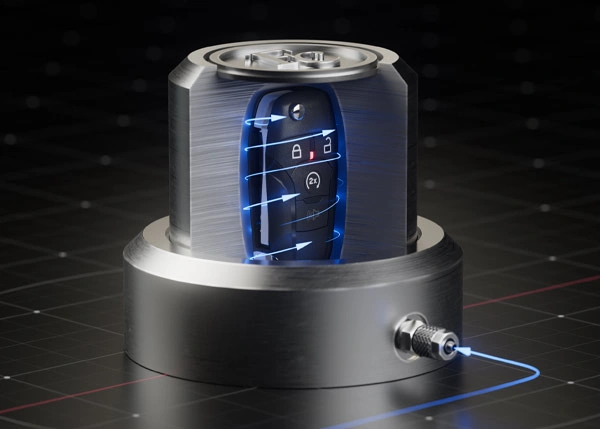

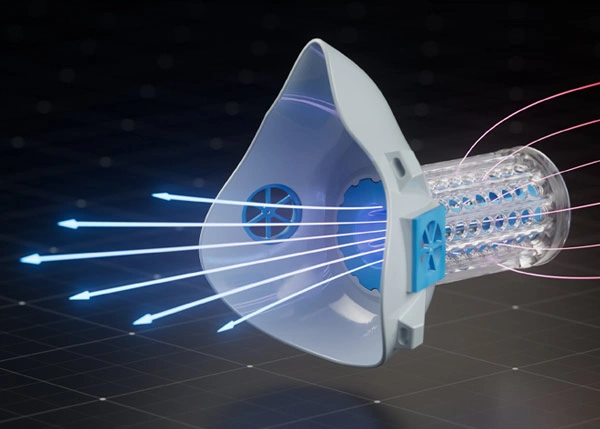

Sealed-part testing

Test air-tightness of products that are already hermetically sealed

-

Ramp testing

Check activation pressures for devices such as pressure-relief valves and actuators

-

Blockage testing

Include checks for minimum flows alongside leak tests

-

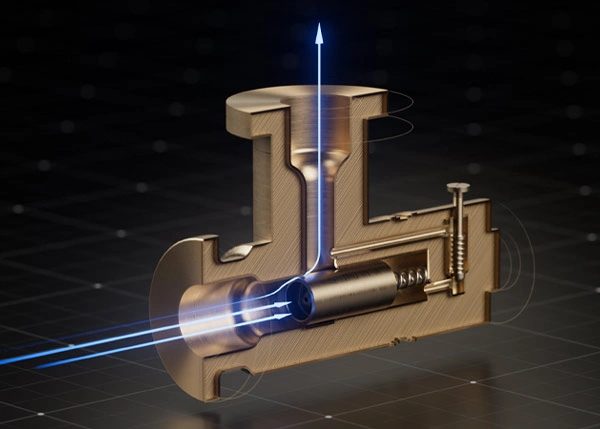

Pressure-decay test

Our world-leading differential pressure sensor detects leaks as low as 0.001ml/min

Intuitive & fast touchscreen display

- Clear numerical values, detailed graphing and easy-touch button

- Quickly choose between 300 configurable products, each with up to 16 customisable steps

- Data Logger function allows you to browse and export all of the data from your last 1,000,000 product tests

- Change settings and configure tests quickly and easily with the intuitive icon-based menu system

Applying pressurised air or gas to a product is one of the most widely-used, accurate and convenient leak test methods, finding use across the manufacturing sector to ensure product quality and safety

Communications

- User-programmable electrical I/O connectors

- User-programmable pneumatic Outputs

- Modern industrial communication interfaces such as PROFINET and EtherNet/IP

- Other communication modes such as RS232, RS485, USB and standard TCP/IP over Ethernet